|

Abron R 750 Bismaleimide Resin

Abron R 750 Bismaleimide Resin Specification

- Type

- Polyimide Resin

- Grade

- Industrial Grade

- Purity(%)

- 99%

- Application

- For Laminating Resins

Abron R 750 Bismaleimide Resin Trade Information

- Minimum Order Quantity

- 1 Kilograms

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 1 Kilograms Per Day

- Delivery Time

- 15-60 Days

- Main Export Market(s)

- Western Europe, Australia, North America, Eastern Europe, Central America, Middle East, South America, Asia, Africa

- Main Domestic Market

- All India

About Abron R 750 Bismaleimide Resin

PRODUCT TRADE NAME : ABRON R 750

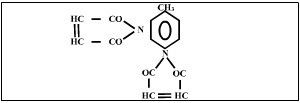

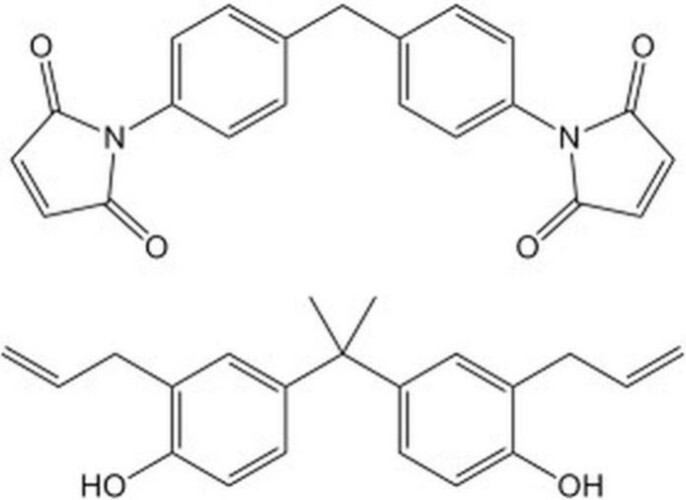

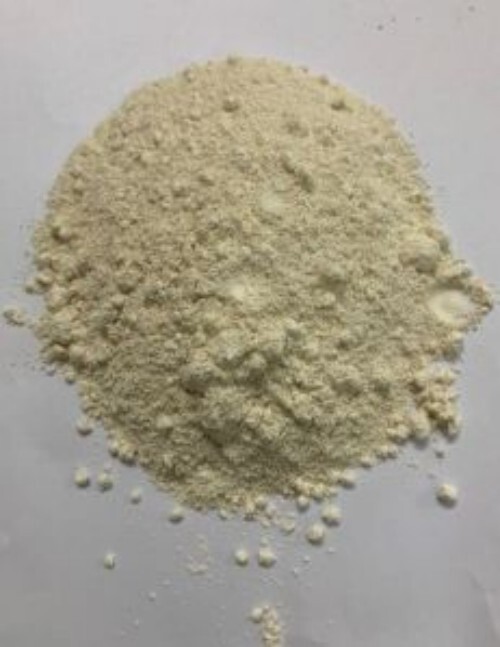

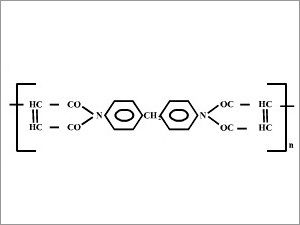

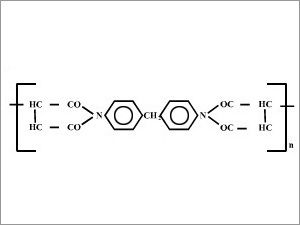

PRODUCT TYPE : POLYIMIDE RESIN (Bis-itaconimide type) Powder Resin

As a result of the efforts of Indian Space Research Organization to develop a processible polyimide, a prepolymer having excellent processability, stability at room temperature and with moderate cure temperatures was developed. Composites made from this prepolymer have yielded components for space and aerospace applications. ABRON-R 750 is being manufactured by A B R ORGANICS LIMITED with the license from Indian Space Research Organization.

ABRON-R 750 is highly amenable for polar & filament winding technology also. The prepregs made from ABRON-R 750 have a long shelf life of 3 to 6 months at room temperature.

GENERAL PROSEDURE FOR MAKING LAMINATES

Silica/Glass/Carbon cloth is impregnated with the resin solution. The solvent is allowed to evaporate (at 55 60C when DMF is used as an solvent). The prepreg should have resin content of 35 40% weight.

The tack & drape of the prepreg is controlled by adjusting the residual solvent content.

The prepregs are stacked in mold and heated to 120C and held for one hour under 60 psi pressure. The mold temperature is raised to 160 165 C as a second step and maintained for another hour. Final cure is done by heating the mold to 200 220 C for 2 hours under pressure. The laminate is released after cooling under pressure to 80 100 C. Post curing is to be done at about 125 C for 6 hours.

This procedure, however is not same for all shapes and thickness of laminates. The exact cycle has to be determined based on trials.

APPLICATIONS

- Aerospace & space applications as resin matrix for composites

- Slot wedges for locomotive traction motors

SPECIFICATIONS OF ABRON R 750

| State | Fine Powder |

| Colour | Light Pinkish Brown |

| Specific Gravity at 25C | 1.1 |

| Solubility | NMP / DMF |

| Bulk viscosity of 40% Solution | 40 100 cP |

| Shelf life of Resin Powder | 6 months at ambient temperatures (< 400 C ) |

| Service Temperature | -200 to +300C |

| Cure Temperature | 200 C 230 C |

| Dielectric Constant | 80 90 KV/mm |

| Surface Resistivity at 25 C | 0.5 X 1014 Ohm.cm |

| Volume Resistivity at 25 C | 2.9 X 1014 Ohm.cm |

| Tan d at 25 C | 0.004 |

| Volume Resistivity at 200 C | 4.7 X 1012 Ohm.cm |

| Tan d at 200 C | 0.025 |

MECHANICAL PROPERTIES OF LAMINATES (ASTMD 1184)

CARBON FIBRE ( UNIDIRECTIONAL)

| TENSILE STRENGTH | 8 X 103 kg/cm2 |

| FLEXURAL STRENGTH | 5.5 x 103 kg/cm2 |

| INTERLAMINAR SHEAR STRENGTH | 305 kg/cm2 |

GLASS FIBRE ( UNIDIRECTIONAL )

| TENSILE STRENGH | 5.2 X 103 kg/cm3 |

| FLEXURAL STRENGTH | 5.0 X 103 kg/cm3 |

| INTERLAMINAR SHEAR STRENGTH | 135 kg/cm2 |

ELECTRICAL PROPERTIES OF GLASS POLYMIDE COMPOSITE

- Dielectric Constant at 10 KHz frequency with 3.3 mm thick laminate = 2.1

- Descipation factor at 10 KHz frequency with 3.3 mm thick laminate = 0

- a) Electromagnetic radiation transparency with unidirectional glass/ PI laminate at 11.9 G.Hz - 89%

- b) Glass cloth PI laminate - 52% c) Glass cloth-epoxy laminate - 5 6%

| Tensile strength | 400 Mpa |

| Flexural strength | 450 Mpa |

| Inter Laminar Shear strength | 25 Mpa |

| Resin content | 26 to 28% only |

| Density | 1.8 1.9 gm/cc |

The above properties meet the requirements of composites functioning uptoo 220C and at 400C for short duration application.

MECHANICAL PROPERTIES OF LAMINATES BASED ON ABRON R 750

| Composite systems | Tensile strength 103 kg/cm2 Av S.D | Flexural strength 103 kg/cm2 Av. S.D | Interlaminar shear Strength kg/cm2 Av. S.D |

| ABRON R 750/carbonUnidirectional | 8.094 0.055 | 5.79 0.565 | 305.55 23.22 |

| ABRON R 750/glassUnidirectional |

| 8.614 1.15 | 325.9 6.30 |

| ABRON R 750/glass Cloth |

| 3.62 0.11 | 250.9 5.8 |

MECHANICAL PROPERTIES OF THERMALLY AGED PROPERTIES

| Temperature0 C | Flexural strength | ILSS |

| ABRON R 750 | ABRON R 750 | |

| 30 | 2530 | 325 |

| 150 | 2741 | |

| 175 | 2806 | |

| 200 | 2840 (2261)* | 291.5 |

| 250 | 3022 | 300 |

Value obtained after soaking the sample for 100 hrs at 200C.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Bismaleimide Resins and Monemers Category

ABRON BR 720

Price Range 2000.00 - 2700.00 INR / Kilograms

Minimum Order Quantity : 1 Kilograms

Application : For Laminating Resins

Grade : Industrial Grade

Type : Other, Polyimide Resin

ABRON MTB

Price 9900 INR / Dram

Minimum Order Quantity : 100 Drams, Dram

Application : For Laminating Resins

Grade : Industrial Grade

Type : Other, Polyimide Resin

Abron BR 732 Bismaleimide Resin

Price 2000.00 INR / Kilograms

Minimum Order Quantity : 1 Kilograms

Application : For Laminating Resins

Grade : Industrial Grade

Type : Other

ABRON PBM

Price Range 1800.00 - 15000.00 INR / Kilograms

Minimum Order Quantity : 1 Kilograms

Application : For High Performance Adhesives

Grade : Industrial Grade

Type : Other

|

ABR ORGANICS LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry