|

Bismaleimide Resin

Bismaleimide Resin Specification

- Type

- Bismaleimide Resin

- Grade

- Industrial Grade

- Purity(%)

- 98%

- Application

- For High Performance Adhesives

Bismaleimide Resin Trade Information

- Minimum Order Quantity

- 1 Kilograms

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 1 Kilograms Per Day

- Delivery Time

- 15-60 Days

- Main Export Market(s)

- South America, Western Europe, Central America, Eastern Europe, Middle East, Asia, North America, Australia, Africa

- Main Domestic Market

- All India

About Bismaleimide Resin

Our enterprise has gained immense recognition by manufacturing, exporting and supplying superior grade Bismaleimide Resin. This resin is processed with high precision under the stern supervision of our adroit professionals by making use of the best grade chemical substances. It is a mixture of epoxy resin that is widely used in printed circuit boards. Further, this Bismaleimide Resin can be availed from us in varied packaging options and at economical prices.

Features:

- Accurate composition

- Safe to use

- High reactivity

- Precise pH value

Typical Physical Properties of ABRON BR 720

RESIN Uncured Resin | Appearance | Yellow |

CURED RESIN | Colour | Brown |

PROPERTIES OF ABRON BR-720 LAMINATES

Testing Standard | BS 3953 PI - 1 |

Reinforcement | Glass Fabric |

Resin | Polyimide |

Colour | Dark Brown |

Mechanical Properties

Felxural Strength (ISO 178), | 1 2000C | 500 MPa 360 MPa |

Modulus of Elasticity (ISO178) | 1 | 25,000 MPa |

Compressive Strength (ISO 604) | 1 | 650 MPa |

Izod Impact Test (ISO 180/2A) | 1 | 55 kj/n2 |

Shearing Strength (EN 60893-2) | 1 | 70 MPa |

Tensile Strength (ISO 527) | 1 | 300 MPa |

Electrical Properties

Electric Strength (IEC 243-1) | 2 | 20 kv/mm |

Permittivity (IEC 250) | 3 | 4.0 at 50Hz. |

Dissipation Factor (IEC 250) | 3 | 0.01 at 50 Hz. |

Insulation systems (IEC 167) | 4 | 1000 M ? |

Comparitive Tracking Index (IEC 112) | 1 | 250 CTI |

PHYSICAL AND THERMAL PROPERTIES

Thermal Indurance Index, 20,000 hrs. (IEC 216) | - | 180 - 2400C |

Flammability (IEC 707) | 1 | FV 0 |

Density (IEC 1183-A) | 1 | 1.95 gm/cm3 |

Water absorption (IEC 62-1) | 4 | 15 mg. |

Conditioning:

- 24h/230C/ 50% RH.

- 24h/230C/50% RH + 1h in oil at 900C.

- 96h/1050C + 1h/230C/20% RH.

- 24h/500C + 24h in water at 230C.

- 96h/1050C + 1h in oil at 900C.

GENERAL METHOD OF PREPARATION OF LAMINATES

- Prepare a 45 - 50 % solution of ABRON BR720 in dry NMP/ DMF/ DMAc.

- Use this solution to impregnate glass-fiber fabrics and then dry at 1600C for 10 minutes to obtain a B-stage prepreg.

- Stack required number of the B-stage prepregs between aluminium foils / mylar sheets.

- Place the stack between heated press plates at a temperature of 1200C.

- Immediately apply a pressure of 210 psi to 800 psi depending upon the thickness.

- Increase the temperature progressively to 1800C in 30 minutes for stack not thicker than 3/8 in.

- Cure the laminate at 1800C for 1 -2 hrs.

- Remove the laminate from the hot press at 1000C and post cure it for 16 - 24 hours at 2500C.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Resin Category

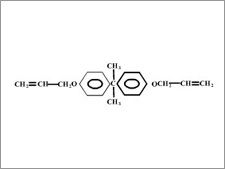

Diallyl Ether Bisphenol

Price Range 1800.00 - 15000.00 INR / Kilograms

Minimum Order Quantity : 1 Kilograms

Grade : Industrial Grade

Application : For High Performance Adhesives

Type : Other, Bismaleimide Resin

Purity(%) : 95%

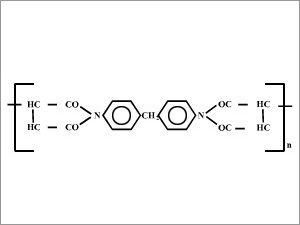

Bismaleimide Resin Chemical Powder

Price Range 1800.00 - 15000.00 INR / Kilograms

Minimum Order Quantity : 1 Kilograms

Grade : Industrial Grade

Application : For High Performance Adhesives

Type : Other, Bismaleimide Resin

Purity(%) : 99%

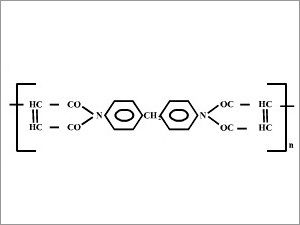

Abron BR 720 Bismaleimide Resin

Price Range 2000.00 - 2300.00 INR / Kilograms

Minimum Order Quantity : 1 Kilograms

Grade : Industrial Grade

Application : For Insulating Coating

Type : Other, Polyimide Resin

Purity(%) : 97%

Solid Phenolic Resin

Price Range 270.00 - 900.00 INR / Kilograms

Minimum Order Quantity : 1 Kilograms

Grade : Industrial Grade

Application : For Production Of Circuit Boards

Type : Phenolic Resin, Other

Purity(%) : 99%

|

ABR ORGANICS LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry